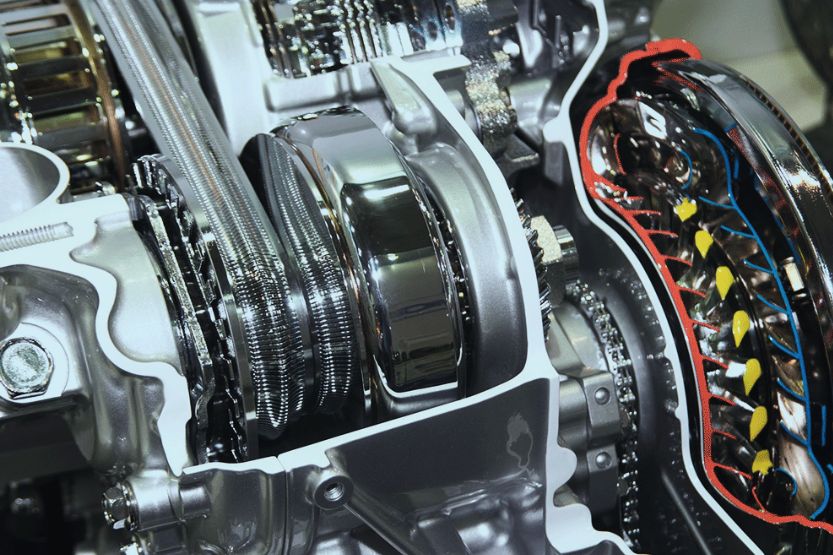

In a sequence-based CVT, a lot of chain things are arranged alongside multiple steel bands layered more than one another, each of that is thin more than enough to easily bend. When A part of the belt is wrapped all over a pulley, the edges of The weather variety a conical surface area.[five][six] While in the stack of bands, each band corresponds to a rather distinct drive ratio, and thus the bands slide above one another and wish adequate lubrication.

Combine harvesters employed variable belt drives as early since the fifties. Lots of small tractors and self-propelled mowers for home and garden use very simple rubber belt CVTs. Hydrostatic CVTs are more common on the bigger models.

Because of the late nineteen eighties, the CVT experienced entered the mainstream because of Subaru. In present day periods, nearly every producer has at the very least one model by using a consistently variable transmission.

Mechanism: It works by using a procedure of variable-diameter pulleys connected by a belt or chain, enabling for seamless adjustments in equipment ratios.

Cause: Grinding noises tend to be a sign of intense use or damage to The inner parts from the transmission, for instance gears, bearings, or even the CVT belt.

Minimized effectiveness. Gears are Just about the most productive methods of mechanical electrical power transmission, with efficiencies as large as 90 percent in many situations.

CVT transmissions can very last just provided that standard transmissions Should they be correctly preserved. Even so, they may be dearer to fix if a thing goes wrong.

Action: Grinding noises really should not be dismissed. Quick Specialist inspection is required, and driving should be minimized to circumvent further hurt.

Result in: Clunking or banging noises might be a result of a number of problems, like worn or ruined interior components including bearings, pulleys, or perhaps the belt. It is also an indication of a more significant mechanical challenge throughout the transmission.

A CVT gearbox doesn't have quite a few relocating parts, so It truly is fairly responsible. It's also predominantly Utilized in small-electrical power purposes, so automobiles running a CVT are frequently fairly unstressed. Assuming that the right read here fluids are accustomed to lubricate the gearbox, and you persist with a regular routine maintenance schedule, then a CVT box really should be no much less responsible than a traditional car or manual.

Though CVTs have many advantages, Additionally they feature a handful of drawbacks that motorists should really concentrate on prior to making a invest in decision.

In advance of we dive in the reliability aspect, let us have a minute to be aware of what a CVT transmission is And just how it works. Unlike common computerized transmissions with fastened gear ratios, CVTs use a unique design that makes use of a set of pulleys connected by a metal belt or chain.

Not like handbook transmissions that need a clutch pedal to disengage the motor from the transmission in the course of gear shifts, automated transmissions trust in an important ingredient called the torque converter to facilitate easy electric power transfer and forestall motor stalling. Sarah Khan • 28/05/2024 Maintenance Transmission Typical Expense To alter Transmission Fluid Transmission fluid is an important element in the right operating of the auto's transmission method. It serves being a lubricant and coolant, guaranteeing easy operation and protecting against abnormal don and tear about the transmission factors Sarah Khan • 28/05/2024 Maintenance Transmission Need to I Alter Transmission Fluid Right after 100k Miles Shifting transmission fluid is a vital maintenance task for vehicles, because the fluid plays a crucial role in lubricating and cooling the transmission components. Over time, the fluid can stop working and become contaminated, bringing about opportunity transmission challenges. Sarah Khan • 28/05/2024

The design basic principle dates again to ahead of the 1930s, with the first style and design meant to change rotary motion to oscillating motion and back to rotary motion using roller clutches.[eighteen] This structure stays in generation as of 2017, to be used with lower-pace electric motors.